🏭 What Is a 3D Print Farm? How to Set One Up and Maximize Profit

The world of 3D printing isn’t just for hobbyists anymore—it’s evolving into a scalable business model. One term that’s gaining traction in 2025 is the “3D print farm.” Whether you're looking to sell online, fulfill client orders, or prototype at scale, running a 3D print farm could be your ticket to consistent income.

In this guide, you’ll learn:

- What a 3D print farm is

- Why they’re gaining popularity

- How to set one up efficiently

- How to keep it profitable

- How tools like AI and image-to-CAD platforms like PrintPal can supercharge your workflow

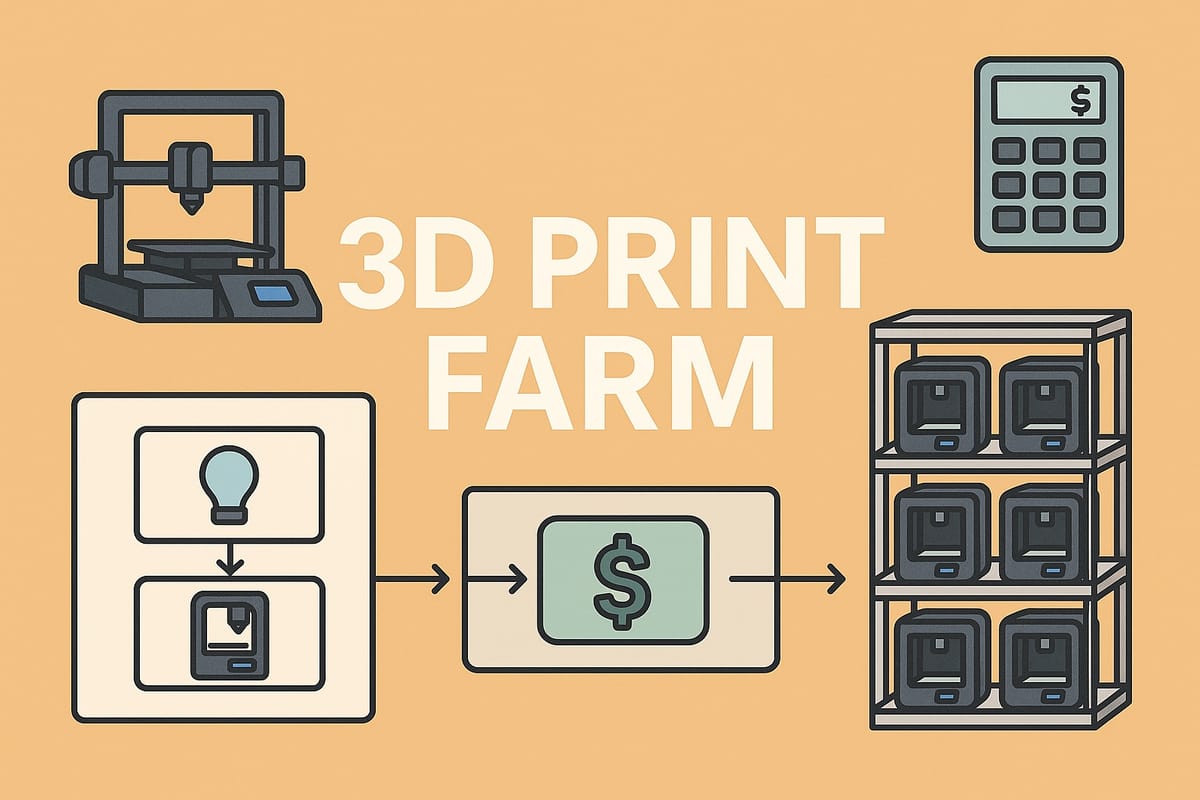

🧠 What Is a 3D Print Farm?

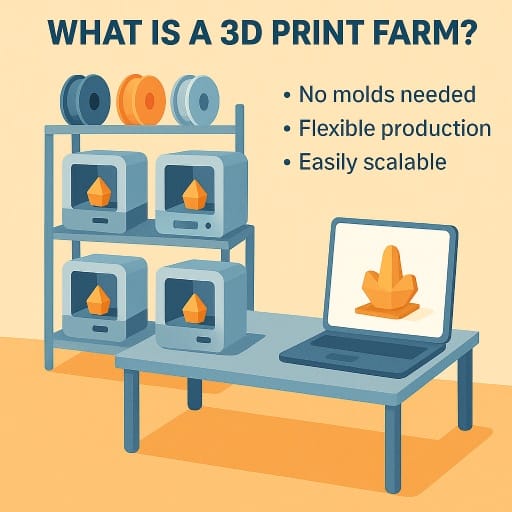

A 3D print farm is a setup consisting of multiple 3D printers operating simultaneously to produce items in parallel. It's like a manufacturing “micro-factory” you can run out of a home, garage, or small studio.

Unlike traditional production, a print farm:

- Doesn’t require injection molds or expensive CNC setups

- Offers near-infinite flexibility in what you print

- Can be scaled horizontally—just add more printers

Print farms are commonly used by:

- Etsy sellers making print-on-demand home goods or cosplay parts

- Prototype shops iterating quickly for engineering clients

- YouTubers and influencers selling branded merch or designs

- Businesses making low-volume, niche products

🏗️ How to Set Up a Print Farm

1. Start Small and Scale

Don’t buy 20 printers right away. Start with 2–5 and learn the ropes. Once you’re profitable and running efficiently, expand.

2. Pick the Right Printers

Most print farms use FDM printers due to their low cost and material flexibility.

Popular models:

- Prusa MK4

- Bambu Lab P1S

- Creality K1 or Ender 3 Neo

- Anycubic Kobra 2

🔧 Key factors to consider:

- Reliability and uptime

- Ease of maintenance

- Firmware with remote management (e.g. Klipper, OctoPrint, Bambu Studio)

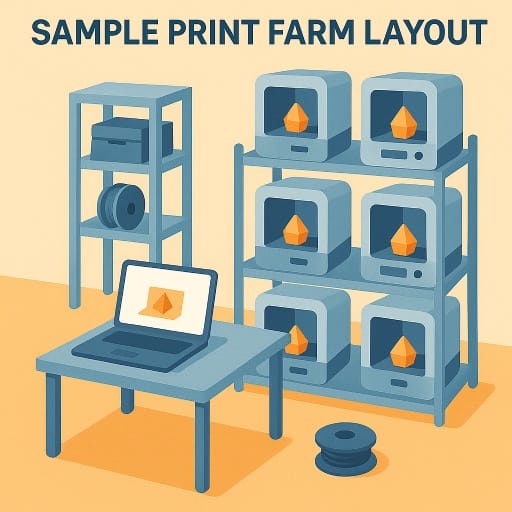

3. Centralize Workflow Management

Use software tools to monitor all your printers from one dashboard:

- OctoPrint (with plugins like OctoFarm)

- SimplyPrint for farm management, queuing, filament tracking, etc

- Klipper + Fluidd/Mainsail

- Bambu Studio/OrcaSlicer

4. Organize Physical Layout

A clean, ergonomic setup saves hours over time:

- Printers in rows or racks

- Dedicated shelves for filament

- Well-ventilated space (especially for resin print farms)

- Label everything

💰 Profitability: How Print Farms Make Money

Here are four proven monetization models:

1. Sell 3D Printed Products

Etsy, Shopify, or Faire marketplaces thrive on customizable, niche goods:

- Phone holders, planters, miniatures, wall hooks, game accessories

- Custom nameplates, cookie cutters, cosplay parts

🔑 Tip: Make small, high-margin items that print quickly and don't have a lot of competition.

2. Offer Local Print Services

Use platforms like Treatstock, MakeXYZ, or 3D Hubs to accept local B2B print jobs.

Great for:

- Architects

- Mechanical engineers

- Inventors who need fast prototyping

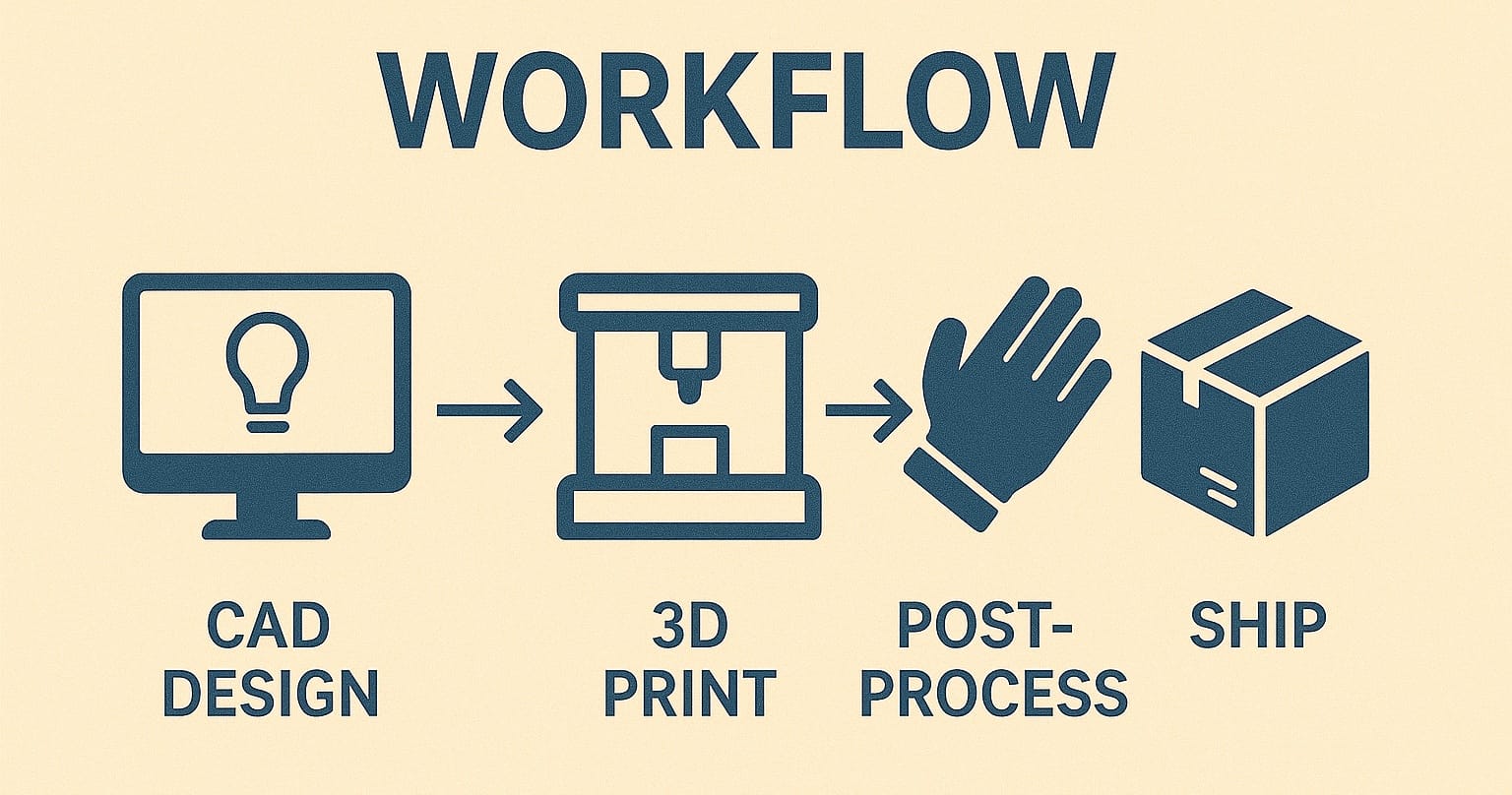

3. Design & Print Bundles

Pair your own designs with printed versions. This gives you a competitive moat.

Designing unique models is often the bottleneck. That’s where tools like PrintPal come in, you can browse thousands of models that are licensed for commercial sales, and you can generate your own designs using AI.

With PrintPal’s image-to-CAD AI, you can:

- Generate an image of your idea (or use ChatGPT to generate one)

- Upload it to PrintPal

- Get a 3D-printable CAD model in minutes

This allows you to:

- Quickly launch new product designs

- Offer custom client requests

- Reduce the need for CAD experience

🧠 Imagine taking a sketch from a client and turning it into a real product on your print farm—all without opening a CAD software.

🔄 Automation Tips

Once your farm grows:

- Use input shapers and auto-leveling sensors to minimize failed prints

- Use AutoPrint by SimplyPrint to automatically queue, print, eject, and repeat your print jobs

- Invest in spool sensors and print queue tools

- Consider auto ejection mods (like belt printers or ejector mods for Bambu and Prusa)

Efficiency = more profit and less burnout.

📈 Is a 3D Print Farm Profitable?

Yes—if you treat it like a business. Here’s a rough breakdown for one operator running five printers full-time:

| Cost Type | Monthly Estimate |

|---|---|

| Filament (10 spools) | $200 |

| Electricity | $80 |

| Maintenance | $40 |

| Total Costs | ~$320 |

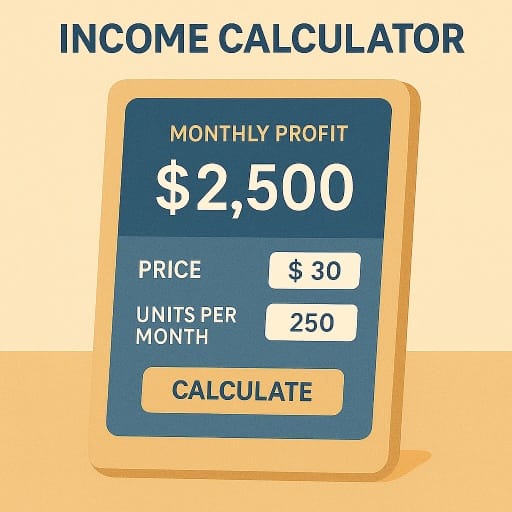

Printing 100–200 items/month with $8–$20 margins can bring in $800–$3,000+ monthly net profit, depending on complexity and niche.

The biggest factors in success:

- Unique product design

- Print quality

- Time efficiency

- Smart scaling

🧠 Final Thoughts

Running a 3D print farm isn’t passive income—it’s real work. But with the right tools, workflow, and products, it’s one of the most accessible ways to enter the world of physical product entrepreneurship.

Use AI to speed up design. Use PrintPal to simplify modeling. Use automation to scale.

Then? Just hit print.

👉 Try PrintPal’s Image-to-CAD Tool and take your first step toward running your own print farm.